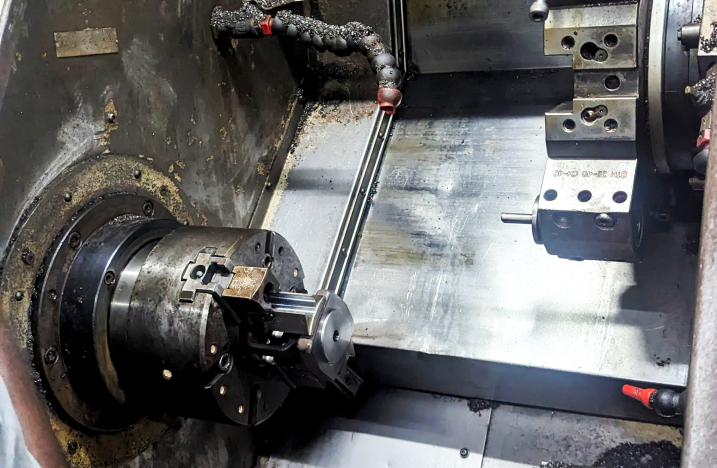

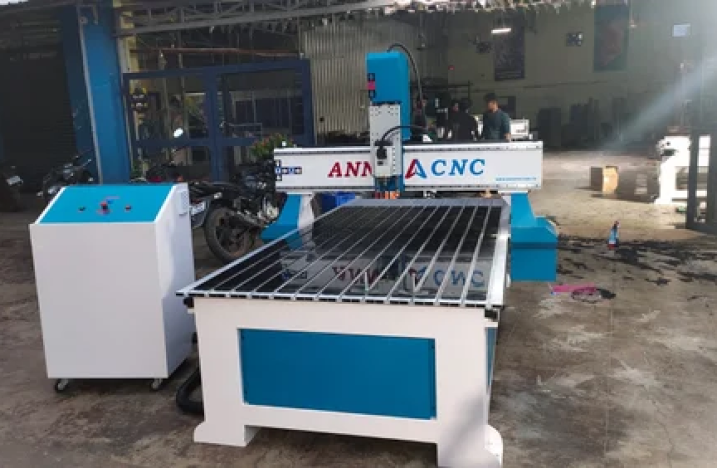

One of the biggest product testing and validation facilities in the industry has been established by Unity Forge.

Global OEMs have authorized Unity Forge's top-notch, cutting-edge advanced fatigue testing facility for the validation of a range of components in order to guarantee a higher and more constant level of quality.

Resonant testing is used in the testing facility to test the bending and torsion fatigue of crankshafts of various capacities, from small passenger vehicle crankshafts to huge marine and rail crankshafts. Electrodynamic shaker systems with capacities ranging from 150 kg to 2700 kg are used to perform resonant fatigue tests under fully reversed loading conditions.

Set up as an ancillary to the Enfield group in Dec 1964, to meet the growing need for high quality forgings, commenced production in 1965. Gradually forged ahead to become a name to reckon with in the forging space.

Get startedOur Social Media Pages

Copyright © 2024 All Rights Reserved By Unity Forge | Designed By Sundar Infographic Analytics